A significant portion of working hours in manufacturing is consumed by tasks such as data retrieval, manual input, and the replication of data across multiple software platforms, each tailored to specific processes. For instance, the technical support team might utilize a ticketing system distinct from the project management tool employed elsewhere in the organization. This necessitates constant updating and data extraction from disparate sources.

The cumulative time expended on these activities is substantial, significantly impacting overall productivity within manufacturing operations.

We spend 4 hours and 55 minutes every week on duplicate tasks. That’s 94 days out of the year spent doing something that could be automated.

All of these tasks, from finding sales info, to locating documents, to approval requests, are great candidates for automation. Here are some real scenarios of how modernized, automated systems overhauled tasks for manufacturers.

6 Examples of Workflow Automation in the Manufacturing Industry

1. Employee Communication

Scenario:

A consumer products leader with 19k employees migrated to the cloud, creating an opportunity to revamp employee communication process. Each region had its own execs and ops, creating communication alignment issues.

Solution:

- Built a communication hub with Power App on SharePoint online

- Central hub for staff to get general role-based messages and apps

- New retail Quality Control mobile Power App capturing photos, GPS, and barcodes

- Power BI for reporting, data visualizations that integrated into SharePoint

Result:

- Power Apps enabled solution development within 14 weeks

- Global staff kept up to date on company-wide updates and events

- Encouraged collaboration across departments and regions

- New low-code framework for creating new role-based apps

2. Estimation

Scenario:

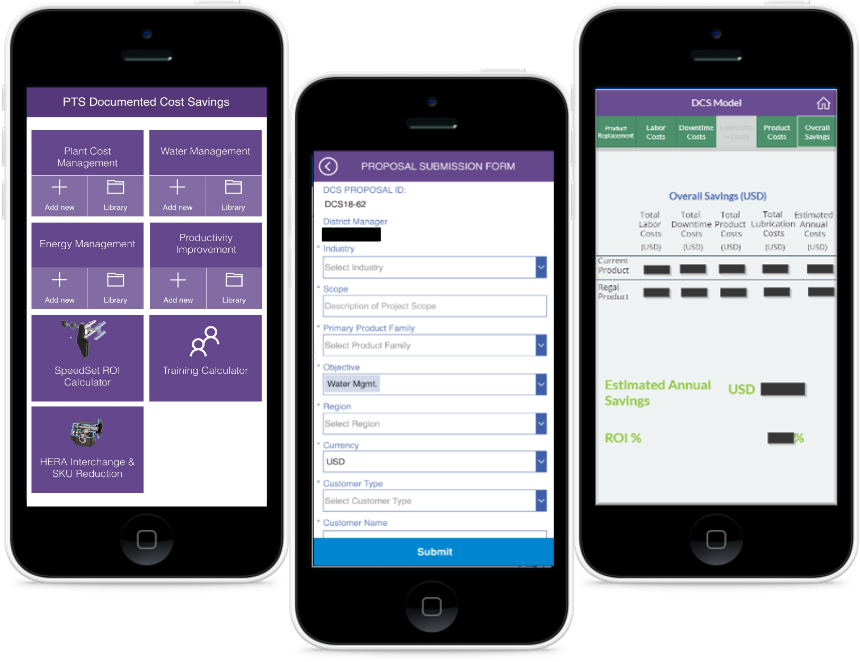

Leading producer of energy efficient motors and power transmission products had a base of sellers who were documenting potential energy cost savings as part of the selling process. This was an Excel based estimating process that was tedious, out-of-date, and extremely error prone.

Solution:

- Deploy a new, easy-to-use Power App based estimator for mobile devices

- Proposals sent to SharePoint Online lists, accessible by sales from any app

- Triggers send proposals to distributors for approval workflow

Result:

- Reduced complexity for preparing cost-savings documents

- Easy-to-use mobile experience, without Excel or email based proposals

- Cost-savings can be tracked, shared with customers and distributors

- Automated business process frees up time for sales team

3. Field Service

Scenario:

Industry leader in electric motor repair and engineering services had 25 repair facilities that served over 4k+ customers and 6k field service jobs annually. Documentation for repairs in the field were paper-based, the tracking process was slow with limited real-time visibility.

Solution:

- Paper forms transformed into tablet-based suite of 20+ Power Apps

- Apps perform calculations and capture photos throughout the process

- Data stored in SQL, synced with Dynamics, used by sales for job status

- Reports are viewable via Power Apps and to external users via portal

Result:

- The company and customers can self-serve reports, without waiting weeks for status

- Teams spend less time manually managing images and repeating calculations

- Customers get consistent repair reports and processing in a unified format

Scenario:

Fuel systems solution provider serving gas stations across the US employs field techs that are dispatched Mondays to inspect tanks and return Fridays with lots of paper reports, time sheets and pictures. At the end of the week, techs would spend hours uploading and manually logging information, which created a long gap between job and invoicing.

Solution:

- Mobile Power Apps track job details, directions, time sheets and photos

- Data syncs to SharePoint lists, reporting through SQL server and SSRS

- Back-end process created report in PDF/Word for third-party report

- Triggers alert the report admin to review and approve reports

Result:

- Within minutes of tech leaving site, job can be reported and invoiced

- Dispatchers know real-time job status, can inform customers

- Minimal training required – solutions looks and feels like an iPhone app

- With automated notifications, jobs no longer fall through the cracks

4. Inventory

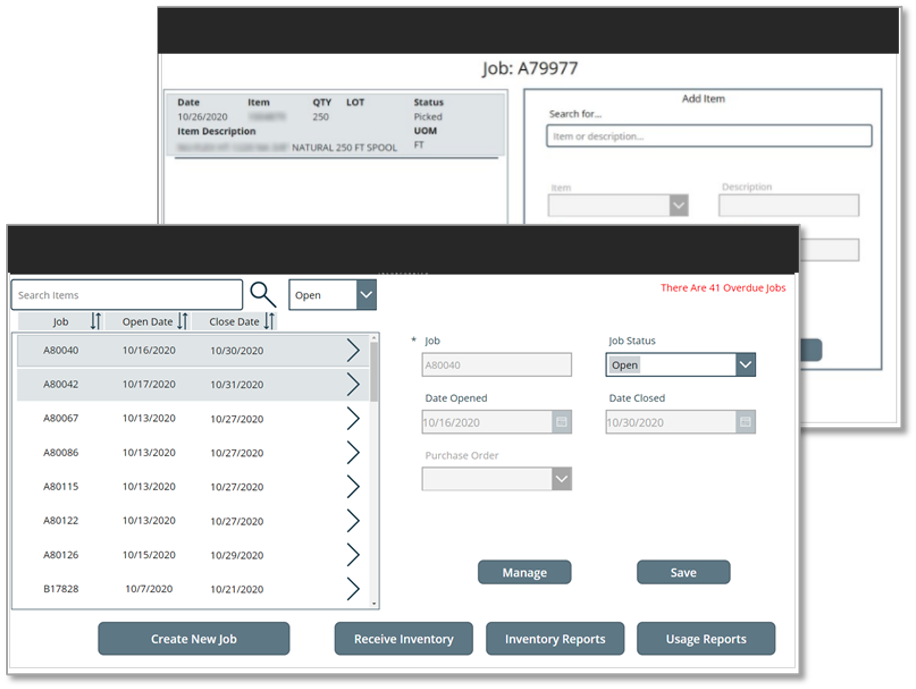

Scenario:

Insulation and product solution leader for manufacturing had teams of employees sharing inventory levels and shipments with Excel and emails. This tedious, manual process was slow and created competitive risk.

Solution:

- Inventory Power Apps used by customers on tablets on shop floor

- Data stored in Dataverse as precursor to Dynamics AX integration

- Customers have parts on consignment, until picked for a job, trigging invoice and replenishment

Result:

- Simple and automated system sed by floor technicians to record inventory used on projects

- Seamless reconciling process: listing inventory, drafting PO and invoicing

- Immediate PO reporting for jobs and inventory used

- On-hand inventory tracking shows products available and restocking needs

5. Sales

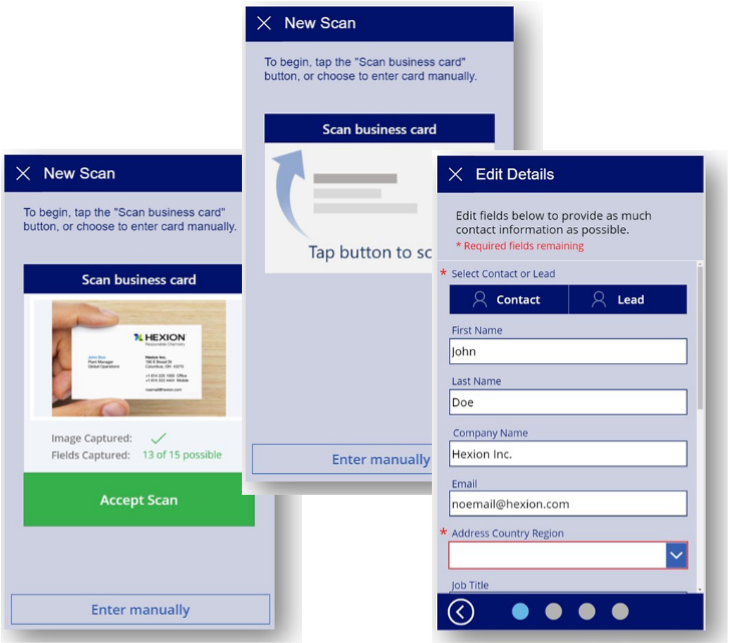

Scenario:

Global provider of water, hygiene and infection prevention solutions was serving close to 3 million customer sites across 170+ countries. The sales reps were spending more than half their time on non-client facing activities with key data spread across multiple, gated and disparate systems.

Solution:

- New Power Apps-based hub, creating unified experience for all sales reps

- Power Apps applications for both mobile and desktop

- Power Automate cloud flows and Power BI reports

- Built on Dataverse, integrated into Dynamics 365 and Azure services

Result:

- Pilot deployed in two months, full rollout to 2k sales reps in four months

- Solution currently deployed to 3k users across five continents in 14 languages

- Sales reps easily and quickly able to access all required data in one place, saving time from navigating between different tools

- Reduced training and onboarding needs

6. Shop Floor

Scenario:

A large US based manufacturing company was using several disparate systems to capture project information. Data was entered manually on spreadsheets and paper forms before being entered again into a different system, taking 3-4 days to process a single form.

Solution:

- Power Apps solution to digitize documents

- Application allowed project managers and stakeholders to view all active projects, see key statistics, and manage the testing and shipping calendars

Result:

- Simplified the collection of data to improve several processes

- Provides timely, accurate, and relevant data reducing waste time

- Collated all tools to one unified system